|

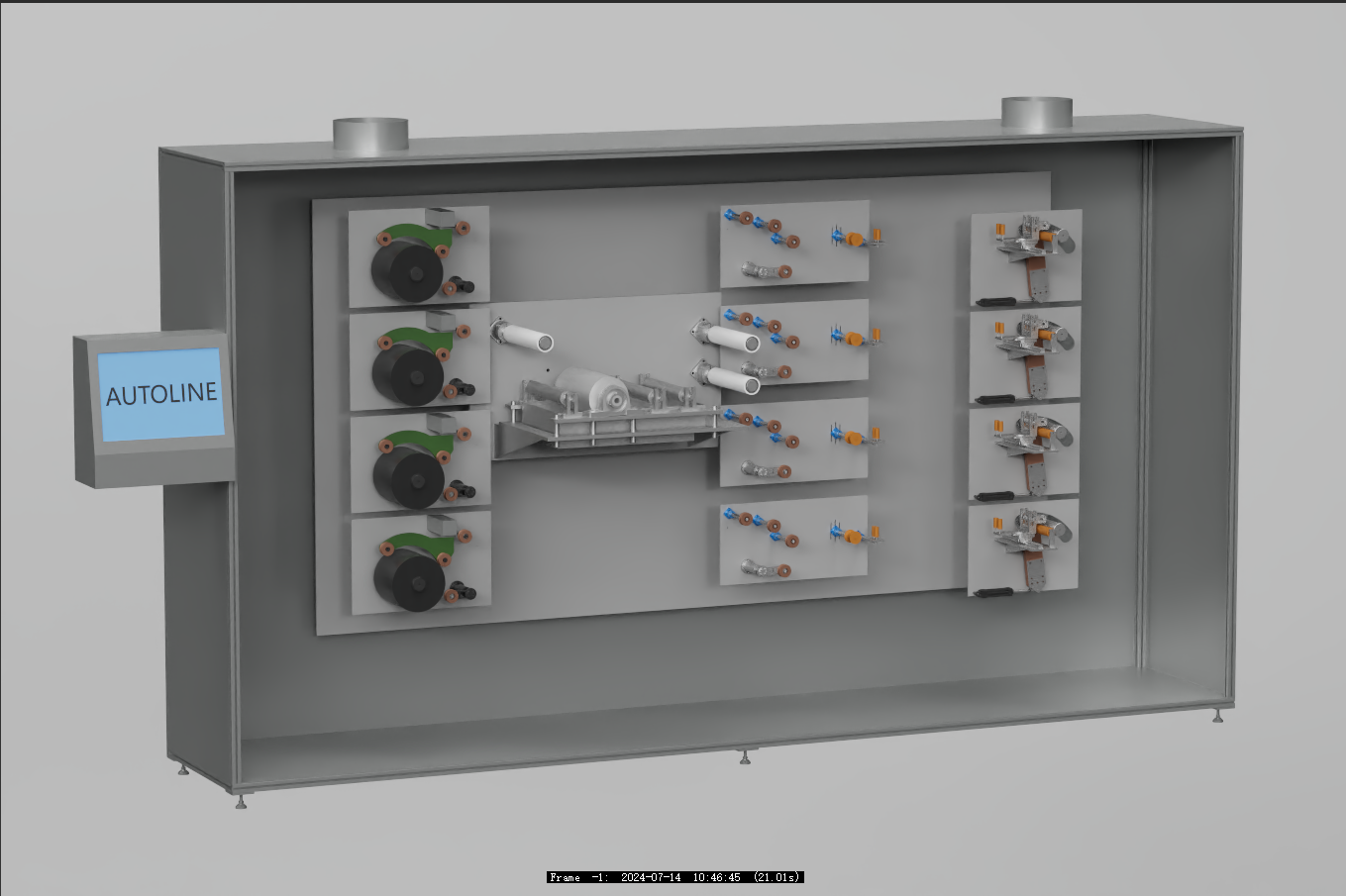

单丝含浸設備 Towpreg Machine

奥特莱的单丝含浸设备可以让单丝含浸树脂能与纤维完美结合。随着我们不断与不同的纤维、树脂生产商合作并理解他们的需要,我们的设备能满足不同的客户需求,开发了稳定可靠的单丝含浸设备。

Autoline's Towpreg Machine allows the impregnation resin to be perfectly combined with the fiber. As we continue to cooperate with different fiber and resin manufacturers and understand their needs, our equipment can meet different customer needs and we have developed stable and reliable towpreg machine.

设备介绍Unique Features:

✓含浸速度快:每分钟含浸速度可达至80米,提高整体产能

Fast impregnation speed: the impregnation speed can reach 80 meters per minute, improving overall production capacity

✓树脂含量精度高:採用全伺服系統,含浸精度達 +/- 1.5%

High resin content accuracy: using a full servo system, the impregnation accuracy reaches +/- 1.5%

✓能配合不同树脂类型 Can be used with different resin types

✓恒速恒张力伺服控制確保性能稳定 Constant speed and constant tension servo control ensures stable performance

适用纤维 Applicable Fiber:

碳纤维、芳纶纤维、玻璃纤维、超高分子量聚乙烯纤维

Carbon Fiber, Aramid Fiber, Fiberglass, Ultra-High Molecular Weight Polyethylene Fiber

设备参数 Specifications:

|

型号

Model

|

HG-M-TP04

|

|

设备尺寸

Dimension

|

6000mm x 1200mm x 3300mm

(冷风柜 根据实际情况定制)

(Cooling cabinets are customized according to actual conditions)

|

|

功位

Work Position

|

4 条纤维同时含浸

4 tows impregnated simultaneously

|

|

速度

Speed

|

5-80m/min,

根据纤维与树脂特性depending on fiber and resin characteristics

|

|

軟件

Software

|

触屏式 PLC全自动

Touch Screen PLC Fully Automatic

|

|

PLC控制系统

PLC System

|

三菱

Mitsubishi

|

|

涂胶精度

Accuracy of Resin Content

|

+/- 1.5%

|

|

树脂量(RC)

Resin Content (RC)

|

25%-42%

|

|

气源

Pneumatic Equipment

|

压力Pressure:6kg/cm^2

流量Flow:1L/min

|

|

电源

Electrical Power Supply

|

380V 50Hz

|

|

总功率

Total Power

|

12KW

|

|

纱筒承重

Max. Bobbin Weight

|

<10kg

|

|

纱筒内径

Inner Diameter of Bobbin

|

76mm(3 inches)

|

|

纱筒长度

Bobbin Length

|

260-300mm

|

|

纱筒最大外径

Max Outer Diameter of Bobbin

|

300mm

|

|